Don't be the slave of your tripod.

Carrying the tripod everywhere sometimes, at least for me, it's a pain in the a.. It's heavy and I have a heavier and a lighter model but to carry it with me with my Powershot G9 seems a little too much for such a small camera.

After taking a Google search I found out a great solution that could be a helper on those occasions when you need to take that quick shot with your Point and Shoot and do not have any tripod or place to put it in.

I also bought another great very useful gadget, but will talk about it on another post.

---Update 06-02-2008---

You can check it out in here.

---//---

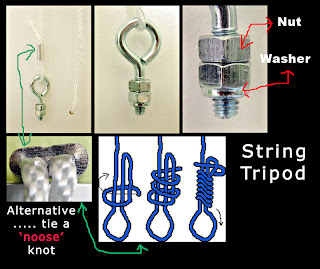

Just build this Image Stabilizer and see how much better your photos and videos can become.

Get professional results, well at least that's what they sold me ;), or maybe would be better to say "Get almost professional results" sounds much better for me :)

This instructional video made by Abby shows you how to build your own stabilizer in 5 minutes for less than €1,00.

It is super light weight and folds up small enough to fit in your pocket.

With this stabilizer, you can hand-hold your camera with shutter speeds at least 3 stops slower than without it.

It works also well with video cameras.

Want to see some more about this easy DIY you can take a look at another wonderful and well written tutorial by shoeBlade with lots of pictures and follow along instructions.

And if you are into Panorama photos you can have this technique applied as fellow photographer Bob Lorentzen show in one of his lessons (Hand held "Virtual Pano Head" Panoramas) or take a look at Philippe Hurbain page for some more resources on the "Virtual Pano Head".

Here is a shot video for panorama shooting presented by Bob Lorentzen:

I guess this would be a great idea to improve stability on my Canon Powershot G9 since, sometimes, it get my grips for not getting that image stable at maximum lens length or low light.

Great solution to travel all the time with you and in your pocket.